GKN announcement about Engineering Support and Services in North America.

We are proud to announce that GKN Sinter Metals Filters will offer, starting January 2nd, 2015, a full engineering and applications support for all porous metal products in North and South America through Wald Krause Engineering LLC, based in Connecticut, USA.

Wald Krause offers a tremendous range of knowledge about applications involving porous metal (with over 25 years of experience in all aspects of porous metal technology) having worked for companies such as Newmet Krebsöge, Mott Corporation, GKN Sinter Metals Filters.

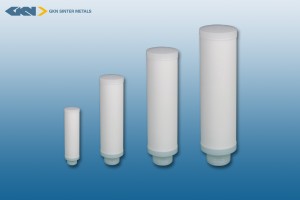

The support includes all process filtration applications from filter element only to design support for industrial filtration processes. In addition, we offer full support for applications, including but not limited to:

– Sparging equipment and solutions (gas to liquid, gas to gas, gas to solid and liquid to liquid)

– Fluidizing, bulking aeration products and solutions

– Flame arresting applications

– Sensor protection

– flow control

– Cryogenic filtration and flow control applications

– Porous metal Chromatography products

– Process filtration

– filter elements

– Aerospace applications

– Any type of solution requiring porous metal media.

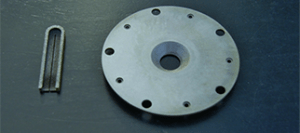

The advantage of using GKN Sinter Metals Filters is based on the availability of full range of various porous metal products, such as high corrosion resistant alloys starting with 316L SS up to Titanium, Porous Bronze filter and products, Porous fiber metal filter products as well as porous plastics.

We can offer any type of required support in order to help you develop the best product and/or solution.

The earlier we start the dialog regarding your requirements the faster and more economically we can to arrive to the solution expected. We are looking forward working with you, to help you achieve the desired solutions.

Please find the contact information below.

Wald Krause

Wald Krause Engineering, LLC

Website: www.wkrause.com

.

.